Morse’s Code on Metrology

Manufacturing stands as a cornerstone of the American economy, relying on a multitude of sciences for its foundation and competitiveness. Metrology is among these disciplines. This fundamental yet often overlooked science underpins the entire manufacturing design and production process.

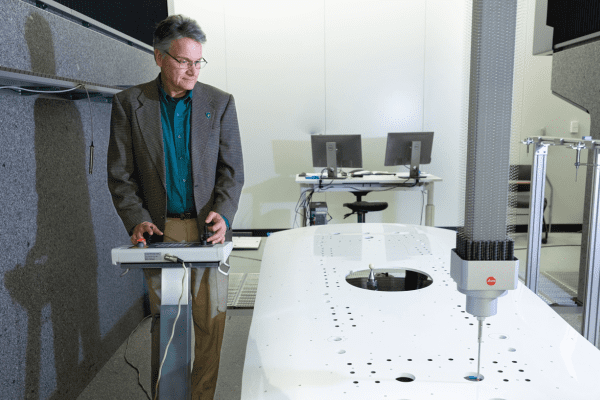

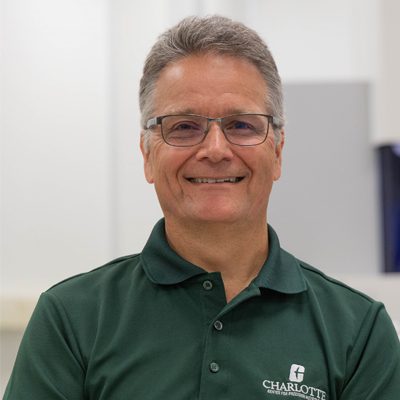

Ed Morse, director of UNC Charlotte’s Center for Precision Metrology, sheds light on this vital science and its role in shaping the landscape of manufacturing.

“THERE IS A PHRASE IN MANUFACTURING THAT IF YOU CAN’T MEASURE IT, YOU CAN’T MAKE IT.”

–Ed Morse, director, CPM

Q: At the most fundamental level: What is metrology and why is it important?

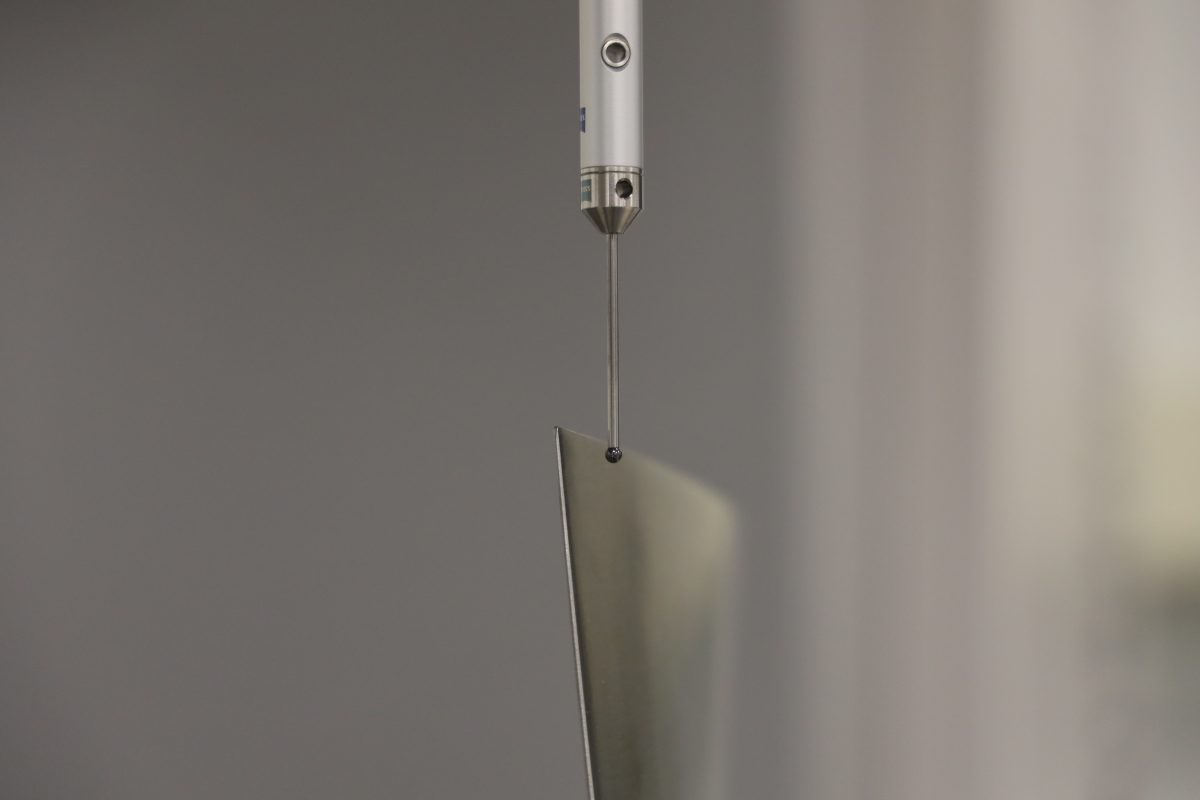

Morse: Metrology is the science of measurement. At Charlotte, our focus revolves around supporting advanced manufacturing through the development of precise measuring systems and techniques. These ensure that manufactured components meet stringent specifications, ultimately driving the economy forward, both domestically and globally.

Q: How does metrology contribute to advanced manufacturing?

There is a phrase in manufacturing that if you can’t measure it, you can’t make it. If you can’t measure a product to determine that it meets specifications, then how would you know that you made it correctly? And that you could make another one?

The industry of metrology is complicated and changing rapidly because new metrology needs arise every time a new manufacturing process develops. For instance, in the last decade or so, 3D printing has become very popular. Now you can make things in a single process that have internal features, which you couldn’t manufacture by conventional methods. So now you must have measurement techniques for these internal features using X-rays. This is an example of what we can do here at CPM.

As another example of how metrology is evolving, the big aerospace companies are always looking for ways to speed up their measurement processes, because they’re measuring huge components and would like them to fit together the first time. For them, a scrap part is very expensive—we help them avoid that extra expense.

Q: Charlotte has garnered support from leading companies like Boeing, Deere, Intel and Raytheon. What benefits do these companies derive from their partnership with CPM?

I like to think of our relationships with our partners as mutually beneficial. The companies get to select research projects that our graduate students will work on that will directly affect their business processes. These projects innovate and expand the boundaries of metrology, which ultimately benefits American manufacturing and the applied research opportunities afforded to our students.

Another benefit is that these industry partners get a chance to know our student researchers and develop relationships with them that often lead to employment. This provides partners exclusive access to specialized talent with industry-specific experience.

Q: Metrology often operates behind the scenes, yet it plays a critical role in ensuring quality. How has Charlotte been able to establish itself as such a strong leader in this oftentimes overlooked field?

People really don’t think much about metrology, its role in society and why it’s important. Once people know about metrology, then I tell them about how UNC Charlotte has a strong program both in research and education. That’s really where we shine: the amount of research we do related to dimensional metrology and the fact that we have graduate courses in various aspects of metrology that produce these incredible students.

Q: Metrology has a rich history. How has the influence of metrology grown over the years?

Metrology actually dates back at least 3,000 years. Interestingly, I have a replica of an ancient Egyptian royal cubit in my office, which was a stone measuring block that was the length of the pharaoh’s forearm from his elbow to the end of his middle finger, plus the width of his palm. The cubit and its replicas were used in the building of the pyramids. And since that time, we have used measurement in all facets of our world.

Request Information about the Ph.D. in Mechanical Engineering